Wood Stove – Wood Fireplace – Wood Insert

Frequently Asked Questions:

1 - What is the best type of wood to burn in my stove or fireplace?

2 - How clean do wood stoves burn?

3 - What’s best, a catalytic or non-catalytic stove?

4 - What can I do to prevent the deposits on the glass of my wood burning appliance?

5 - How can I clean deposits off of the glass?

6 - How much space can my wood burner heat?

7 - Can I convert my wood stove over to a gas system?

8 - Can I convert my wood-burning fireplace to gas?

9 - Why won’t my chimney draft properly?

10 - What is the difference between convective heat and radiant heat?

11 - How often should I get my chimney cleaned?

12 - What are the proper regulations for installing my wood burning appliance?

13 - When I open the stove door, smoke enters the room, how can I prevent this?

14 - How can I child-proof my stove?

15 - What is “Negative Air Pressure” and how does it work?

16 - How much should I expect to pay for a wood burning appliance?

If you have other questions, please feel free to Contact us!

Expert Answers!

1 - What is the best type of wood to burn in my stove or fireplace?

For the best performance while also ensuring the longevity of your wood burning system, burning properly seasoned wood is always the best practice. The wood should be cut, split and left to air dry for a minimum of eight to nine months before it is dry enough to use. Keeping it under cover protected from rain and snow is always a good idea. Never burn wood that contains chemicals that can harm your wood burning appliance as well as the environment. These include driftwood, wood that has been painted, pressure treated wood, wood with nails or screws or particleboard.

When choosing wood to burn, always consider the impact this choice has on your equipment’s performance. The most important factor is making sure the wood is properly dried and that it is cut and split to the proper size. We also recommend burning hard woods like maple or oak.

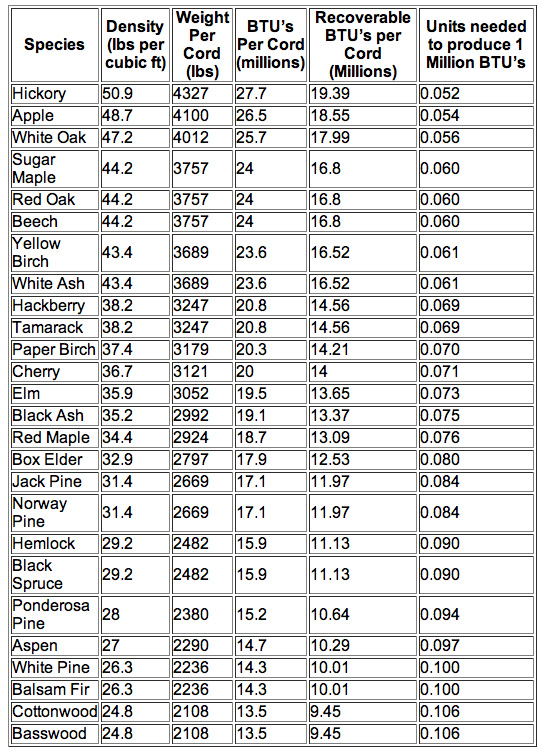

The variety of wood you use will determine the heating value. Every different type of wood has its own characteristics, but all wood, pound for pound, contains essentially the same amount of energy. The main difference in wood varieties is the density. You will get more heat from hard woods versus soft or lighter wood. Therefore, if you purchase a cord of an assortment of wood that mostly consists of hard woods such as hickory and oak, it will cost more than a cord of soft wood such as pine.

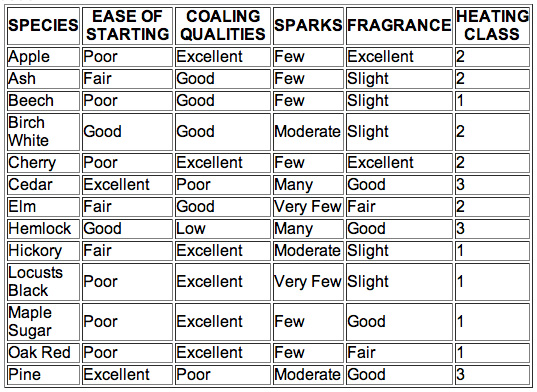

For the most part, when you cut or purchase firewood, it will not be adequately dried. This means that it will still contain lots of moisture. Consider a moisture reader; a small hand-held device that will read the moisture content of the wood. Readings below 25% are best. Other factors to consider when selecting wood include how easily it can be split, ignited and burned. You may also want to consider the amount of smoke it will produce and the wood’s “coaling” qualities. This reference chart should help.

It is helpful to know that “coaling” is the ability of the wood to turn into a bed of hot coal that will last throughout the fire. The wood is more likely to have good coaling qualities if it has a higher density. Also, note that in the heating class column, it is best to have a lower number.

2 - How clean do wood stoves burn?

The smoke from a wood fire is filled with the particles and gases left over from the combustion process. Labs can test the smoke and find the exact amount of particle pollution present. In recent years the standards have mandated strict changes to ensure clean burning. Before the regulations were in place for woodstoves in 1988, an average stove created 70-80 grams of particle pollution per hour. In 1992, the Environmental Protection Agency required that non-catalytic stoves must produce less than 7.4 grams of particles per hour and catalytic stoves, less than 4 grams per hour. The reason for the stricter requirements for catalytic stoves is because the catalytic combustor becomes less effective over time so harsher requirements from the start will result in similar efficiencies toward the end of the appliance’s life.

3 - What’s best, a catalytic or non-catalytic stove?

In order to comply with clean air standards, manufacturers use two different types of re-burn systems in wood burning equipment. The first one uses catalytic technology. A catalytic combustor looks like a honeycomb. Smoke is re-routed through the combustor by closing a damper. Extremely high temperatures in the combustor will burn any remaining by-products in the smoke. A combustor must be cleaned at least annually and most have a life of about 10,000 hours.

The second technology used, in non-catalytic stoves and fireplaces, keeps up with the EPA regulations by using a system of secondary air tubes in the top of the firebox. These secondary burn tubes are used to mix extremely hot air with the smoke and burn those by-products. The benefits of air tubes is that they do not require any regular maintenance and the re-burn system is automatic … … there is no damper to engage or disengage as there is with a catalytic combustor. Secondary burn tubes should last five years or more.

While both types burn cleanly and efficiently, non-catalytic stoves are typically known for their ease of operation. For this type there is only one air controller that controls the heat of the fire … … for more heat increase the amount of air, for less heat (and longer burn times) reduce the air. For catalytic stoves, a damper must be engaged in order to “turn on” the combustor. The operator must monitor the flue gas temperatures to determine the correct time to close the damper.

A magnetic or probe-type thermometer, positioned on the connector pipe about 15 – 18 inches above the top of the stove, is an inexpensive tool to assist you in maintaining proper operating temperatures.

4 - What can I do to prevent deposits on the glass of my wood burning stove?

The glass door on your wood burning fireplace or stove may accumulate deposits from the by-products of the combustion process called creosote. To prevent or reduce the amount of buildup, always burn dry/seasoned wood, build small but hot fires and leave the air control open.

You should always burn wood that has been properly seasoned. Moisture from the logs will create more creosote. Small but hot fires reduce the amount of creosote accumulation because they burn the contents of the fire more completely. This will greatly reduce the amount of smoke produced and provide more heat for your home.

Small, hot fires will also help to burn off the buildup on the glass if it already exists. The final method of prevention of creosote is to burn your fires with the air control open as much as possible. This air will keep the smoke away from the glass, therefore preventing deposits from forming.

Generally speaking: the hotter the fire, the cleaner the glass.

5 - How can I clean deposits off of the glass?

To clean the glass of your wood burning appliance, first make sure that the glass is completely cooled off. It is never a good idea to attempt to clean hot glass. To begin, brush off the inside of the glass with newspapers or paper towels to get rid of any dried up, powdery residue left on the glass. If the deposit on the glass is in a sticky or gummy form, first try to burn a clean hot fire using seasoned wood to burn off the deposit. If this is not successful, our specialty glass cleaner will quickly remove the sticky deposits. When using the cleaner, be sure to follow the directions on the bottle. And, be careful to not allow the cleaner to drip onto the metal parts of the appliance as discoloration may occur. Another possible solution is to use the old fashioned method of cleaning: Dip a damp wad of newspaper into powered wood ash and scrub the glass until the sticky residue comes off.

6 - How much space can my wood burner heat?

There are many factors that affect the answer to this question, including: the type of wood, how dry it is, square and cubic footage, the heat loss from your home, the amount of the sidewall and ceiling insulation, the quality of the windows and doors and the directional orientation of the house. These factors are critical, but the most important factor is the size of the firebox, measured in cubic feet. The larger the firebox, the more fuel you will be able to burn and the more space you will be able to heat.

7 - Can I convert my wood stove over to a gas system?

No, never. This is extremely dangerous. Do not under any circumstances convert a wood burning stove over to a gas system.

8 - Can I convert my wood-burning fireplace to gas?

Converting a wood burning fireplace to LP or natural gas is different from converting a free standing, wood burning stove. Gas logs, fireplace inserts, and even gas stoves can be used to convert a wood burning fireplace to gas. Typically, we will need to evaluate the fireplace to determine the best options. A visit to our show room will also give you a good idea of the various options for converting a wood fireplace to a gas appliance.

9 - Why won’t my chimney draft properly?

There are many reasons for a wood stove that does not draft properly. While stoves must be installed using the most current standards to ensure they are in safe and working condition, the codes do not guarantee that the stove will perform properly.

It is very important to match the correct chimney size with the stove in order to obtain optimal performance. In the past it was thought that a bigger chimney would result in a better draft. But when stoves burn more efficiently, there is less smoke leaving through the chimney. As a result of less smoke, there may not be enough hot air in a large chimney for the system to operate correctly. For the most part, a chimney will need to have a six inch diameter for a wood burning stove. While most zero clearance wood burning fireplaces will require an eight inch chimney. It is always best to keep the chimney as straight as possible and inside the house for as long as possible so the pipe stays warmer. Try to minimize the numbers of offsets and elbows. Try to avoid exterior walls or uninsulated chaseways because the pipe will be cold from the outdoor temperatures. Cold chimneys cause condensation and condensation will lead to creosote building up. Avoid very short or extremely tall chimney’s. And remember; keep the chimney as straight as possible and as warm as possible.

Negative air pressure is also a problem in newer homes. It can cause a stove to not draft properly. Newer homes are built tighter than they have been in the past, so this makes less air available to replace the air used up from the fire. Negative air pressure can also come from basements, or result from clothing dryers, kitchen fans, and exhaust fans that pull air out of the home. For the wood stove to work properly there must be enough fresh air available in the home.

Other factors, not related to the interior of the home include trees around the chimney, the design of the roof, the direction of the wind and how the house is situated on the lot. There are many factors that can cause draft issues, and the effects relevant to your stove can be discussed before the appliance is purchased.

At times though, the draft problems can occur as a result of equipment that was not installed properly. For example, a ceramic blanket above the baffle may get moved from its place and block the gases and smoke from exiting the stove. Sometimes people will place rags or other materials in the chimney for insulation to stop cold air from coming into the home … … and then forget about it when cold weather comes and it is time to use the fireplace or stove again.

10 - What is the difference between convective heat and radiant heat?

Radiant heat, heats objects such as people and the furniture in a room. Convective heat is air that has been warmed by moving through a heat exchanger, typically in your forced air furnace. Think of convective heat as air moving through a heated confined space. Radiant warms objects, like the heat from the sunshine.

11 - How often should I get my chimney cleaned?

The National Fire Protection Association standard states that all chimneys should be inspected and cleaned at least one time each year.

12 - What are the proper regulations for installing my wood burning appliance?

The owner’s manual that comes with the purchase of an appliance will contain detailed drawings and instructions on the proper clearance requirements for a wood burning stove, fireplace or insert. For older stoves that are untested & unlisted, there is a list of default codes (NFPA 211) that must be followed for correct installation.

13 - When I open the stove door, smoke enters the room, how can I prevent this?

To greatly reduce the chance of smoke entering the room, carefully and slowly open the door just a crack, wait a few seconds and open the door the remainder of the way.

14 - How can I child-proof my stove?

While the radiating heat from the stove can be felt around the fire and will serve as a warning sign in this way, a metal mesh or screen shield placed around the stove can also be used to keep children out of harm’s way.

15 - What is “Negative Air Pressure” and how does it work?

Negative air pressure occurs when the pressure inside the home is less than the barometric air pressure outside. Hot air rises, so the upper levels of the home typically have positive air pressure and leave negative air pressure on the lower floors. This is not uncommon in new, tightly built homes that do not allow air to infiltrate. Negative air pressure can cause problems when it overpowers the chimney draft and takes air in through the chimney in an attempt to even out the pressure. Contributors to this problem can include exhaust fans, range hoods, bathroom fans, combustion appliances, central vacuum units and clothes dryers. For very tight homes, this problem must be solved for the entire home, which may include installing a mechanical air make-up system. Oftentimes this problem can also be solved temporarily by simply opening a window.

16 - How much should I expect to pay for a wood burning appliance?

It is unwise to pay too much, but it is worse to pay too little. When you pay too much, you lose a little money, that is all. When you pay too little, you sometimes lose everything, because the item you purchased was incapable of doing the thing it was bought to do. The common law of business balance prohibits paying a little and getting a lot. It cannot be done. If you deal with the lowest bidder, it is well to add something for the risk you run. And if you do that, you will have enough to pay for something better. There is hardly anything in the world that someone cannot make a little worse and sell a little cheaper, and people who consider the price alone are this man’s lawful prey.

By John Rusking (1819 - 1900)

If you have other questions, please feel free to Contact us!

(563) 582-5156

(563) 582-5156